Enhance industrial laundry

with innovative & intelligent

dosing systems

Scale up and optimise every step in large-scale laundries with

our IoT Multiplex range of dosing systems – the leader in

managing operations with real-time reporting & digital libraries.

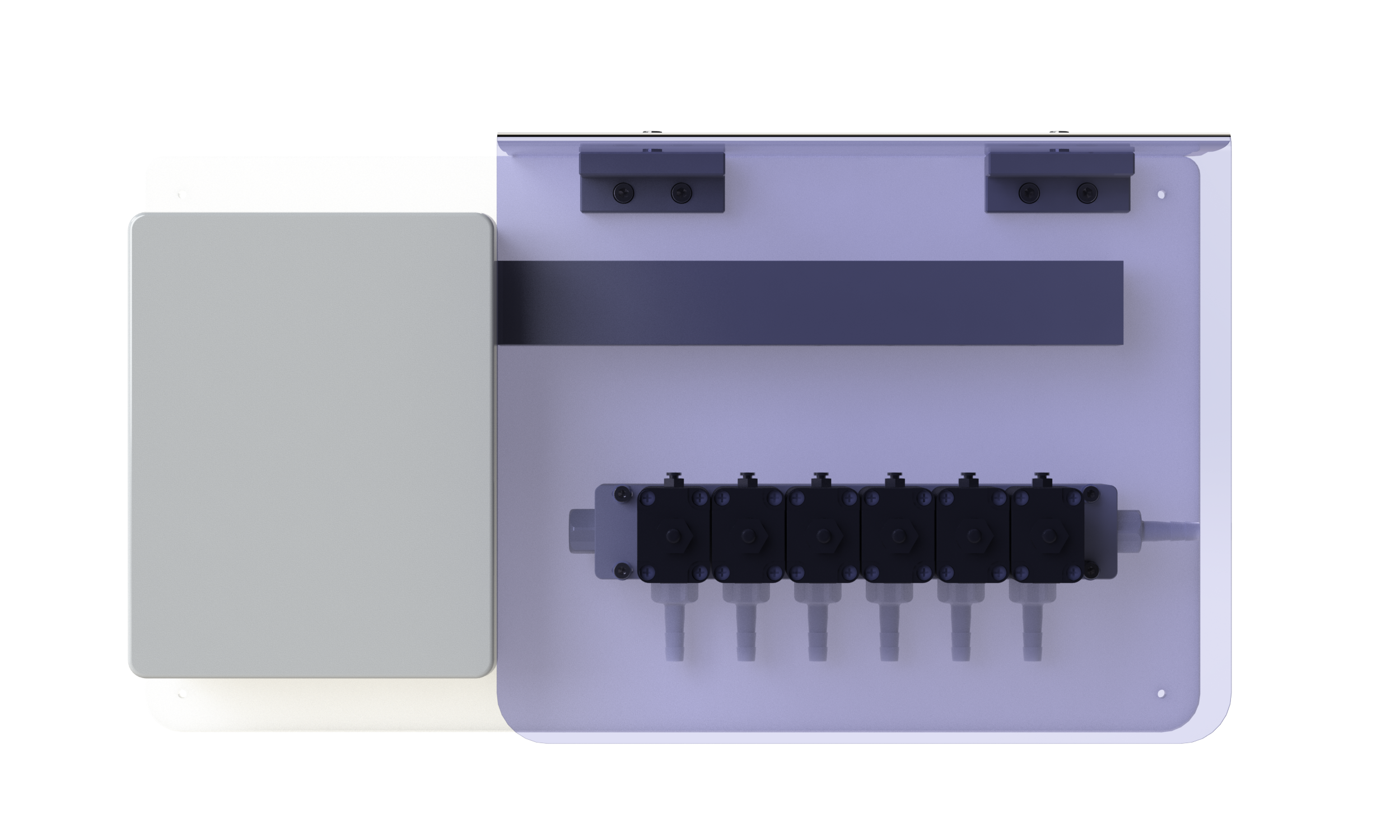

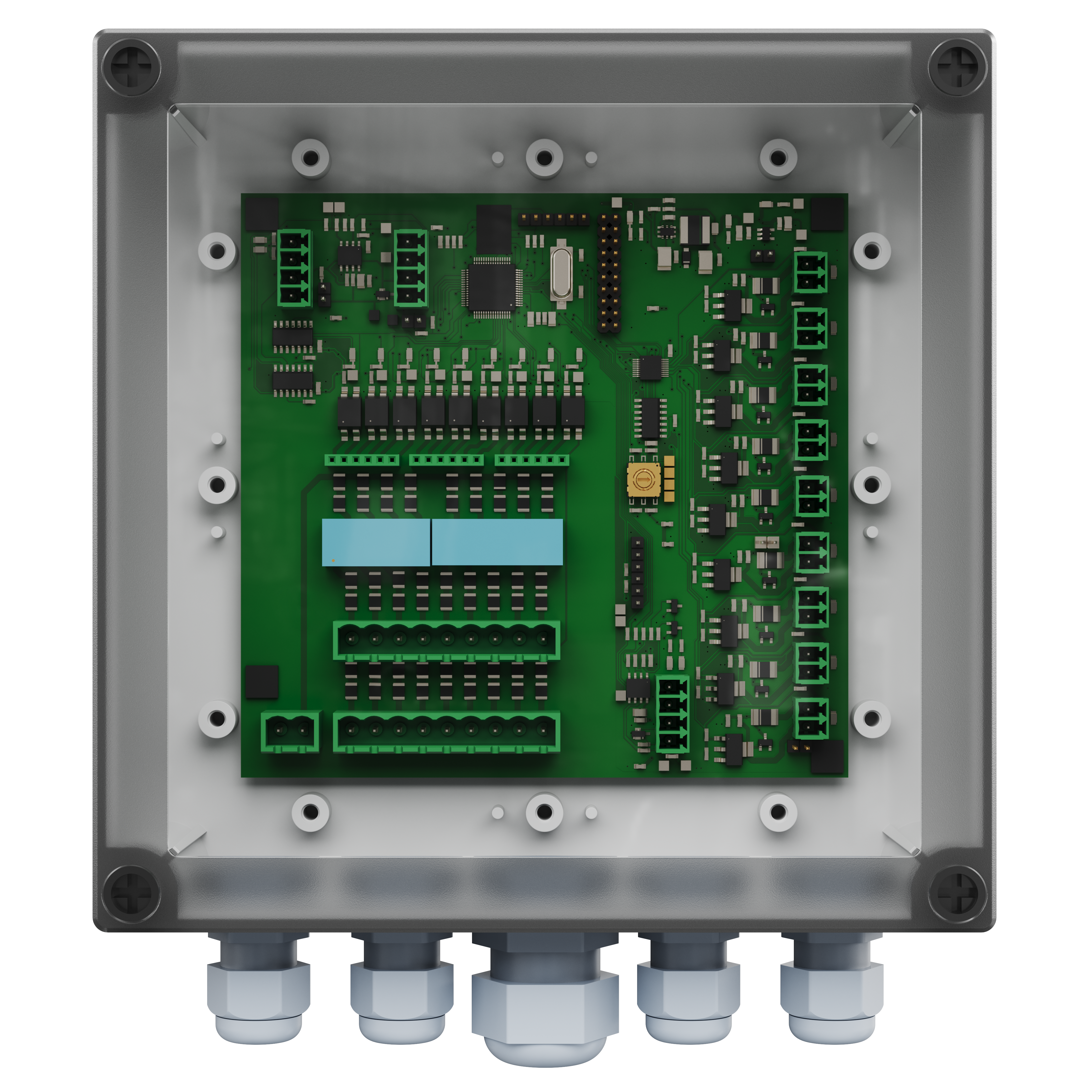

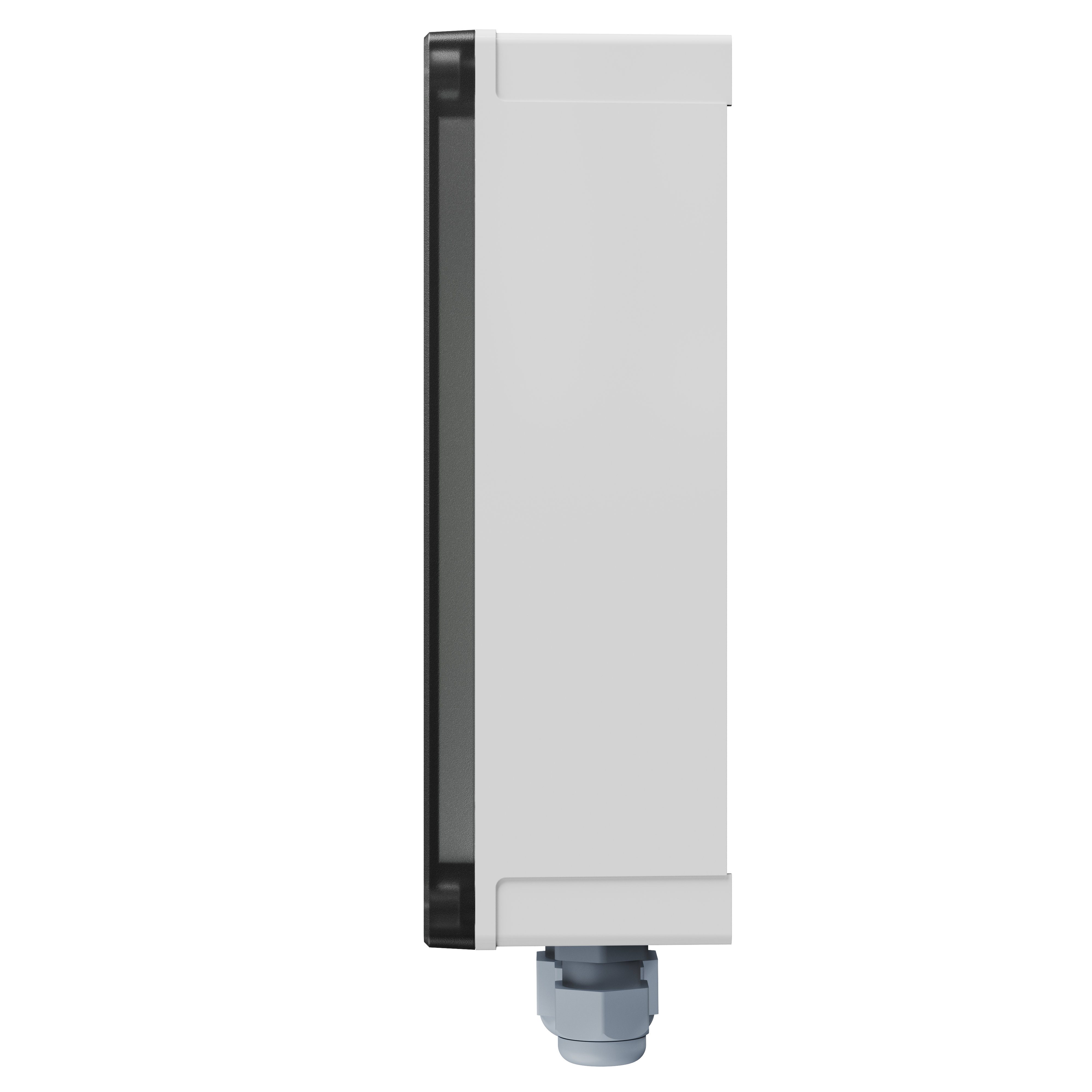

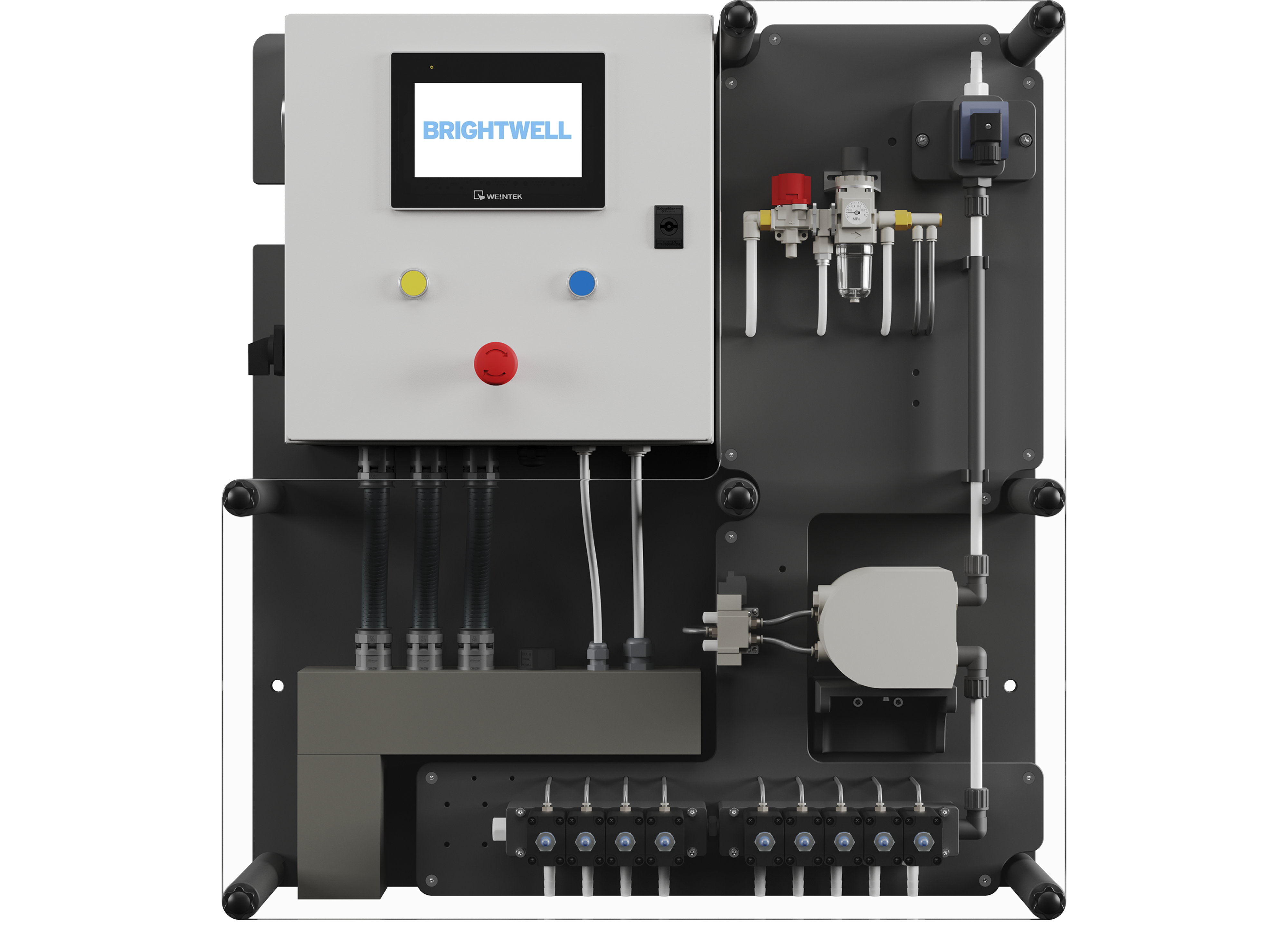

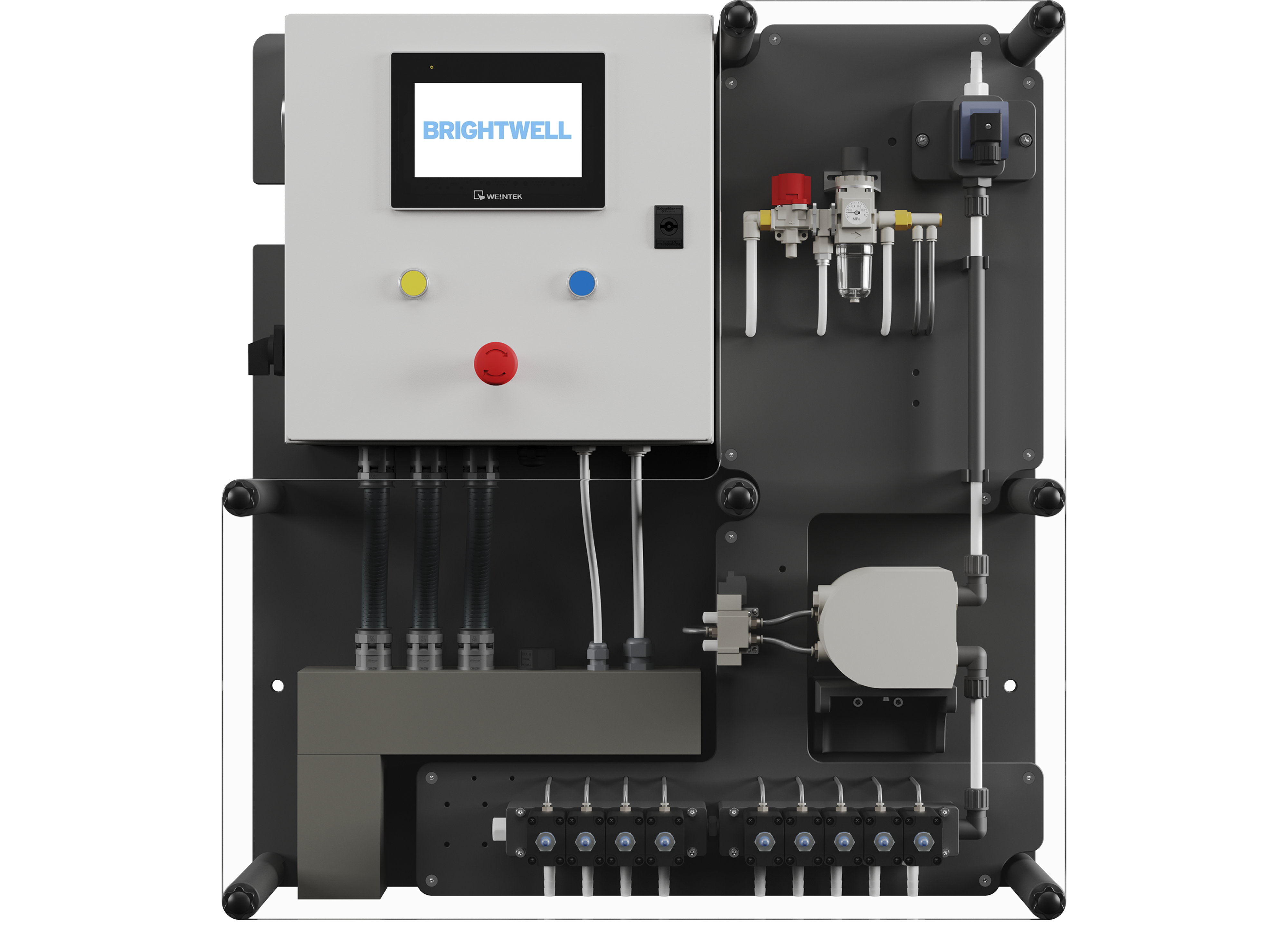

Multiplex, our intelligent large-scale

laundry dosing system

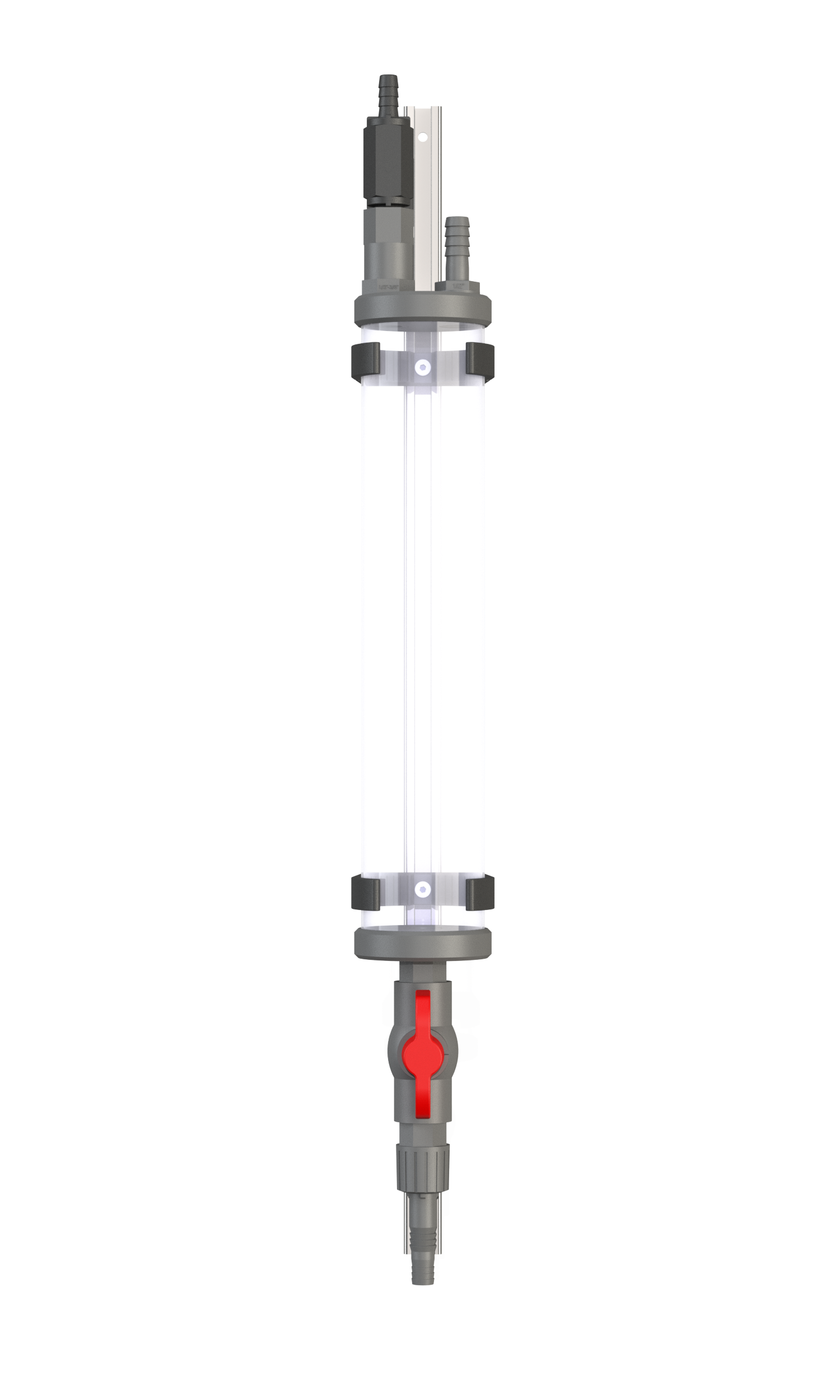

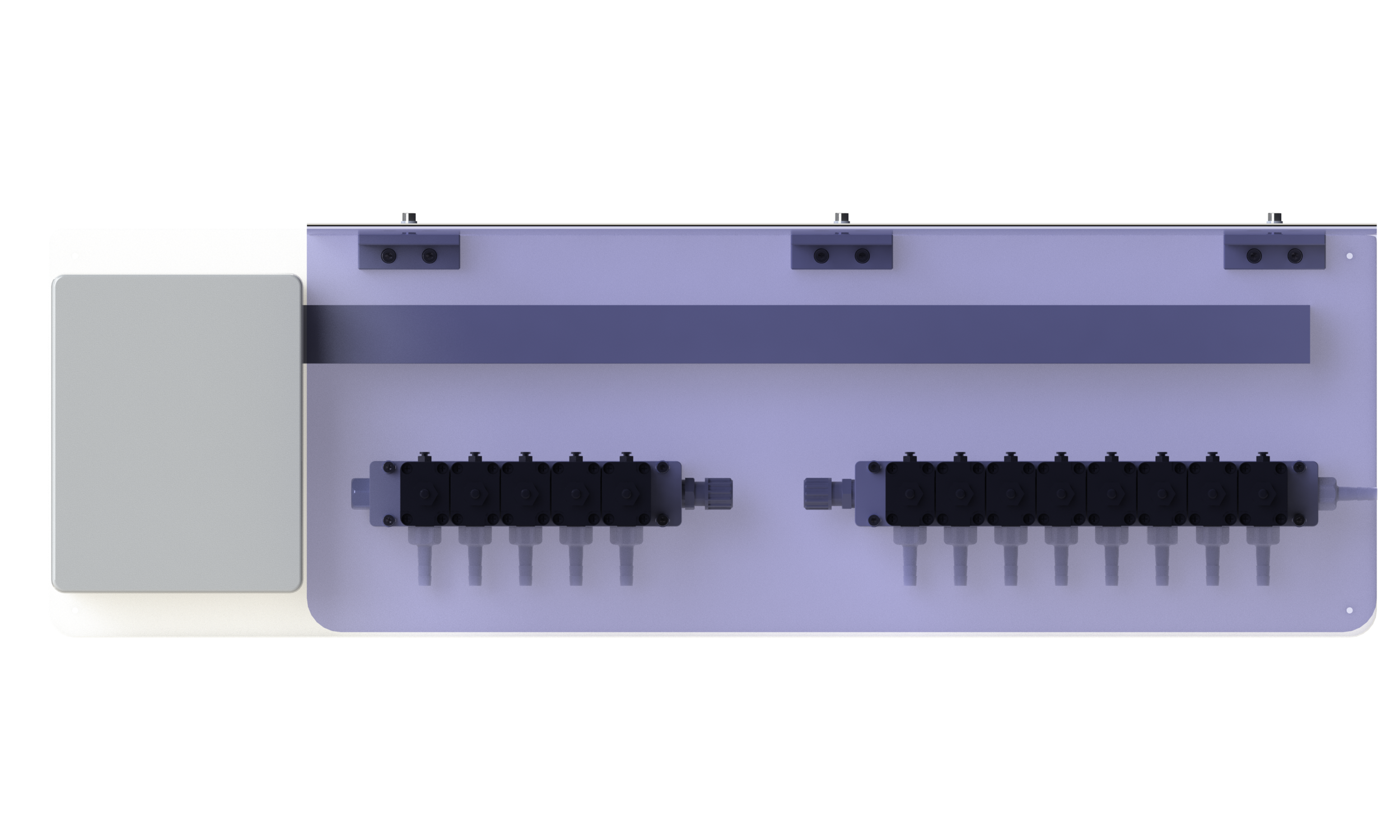

An ideal solution for operations of any size. Choose from our selection of four versatile models,

each capable of handling up to 12 washing machines, accommodating sizes

ranging from 500 to 4000 kg, and managing up to 10 chemicals.

Offering real-time data and digital services

to easily monitor consumption, usage, and cost reports

with organised and clear interfaces.

Comparison Matrix

To help you select the best option for your needs, the table offers a clear summary

of the multiplex range options, configurations, and key specifications.

Costs savings with modularity

Intelligent library and digital services

Reduced maintenance and downtime

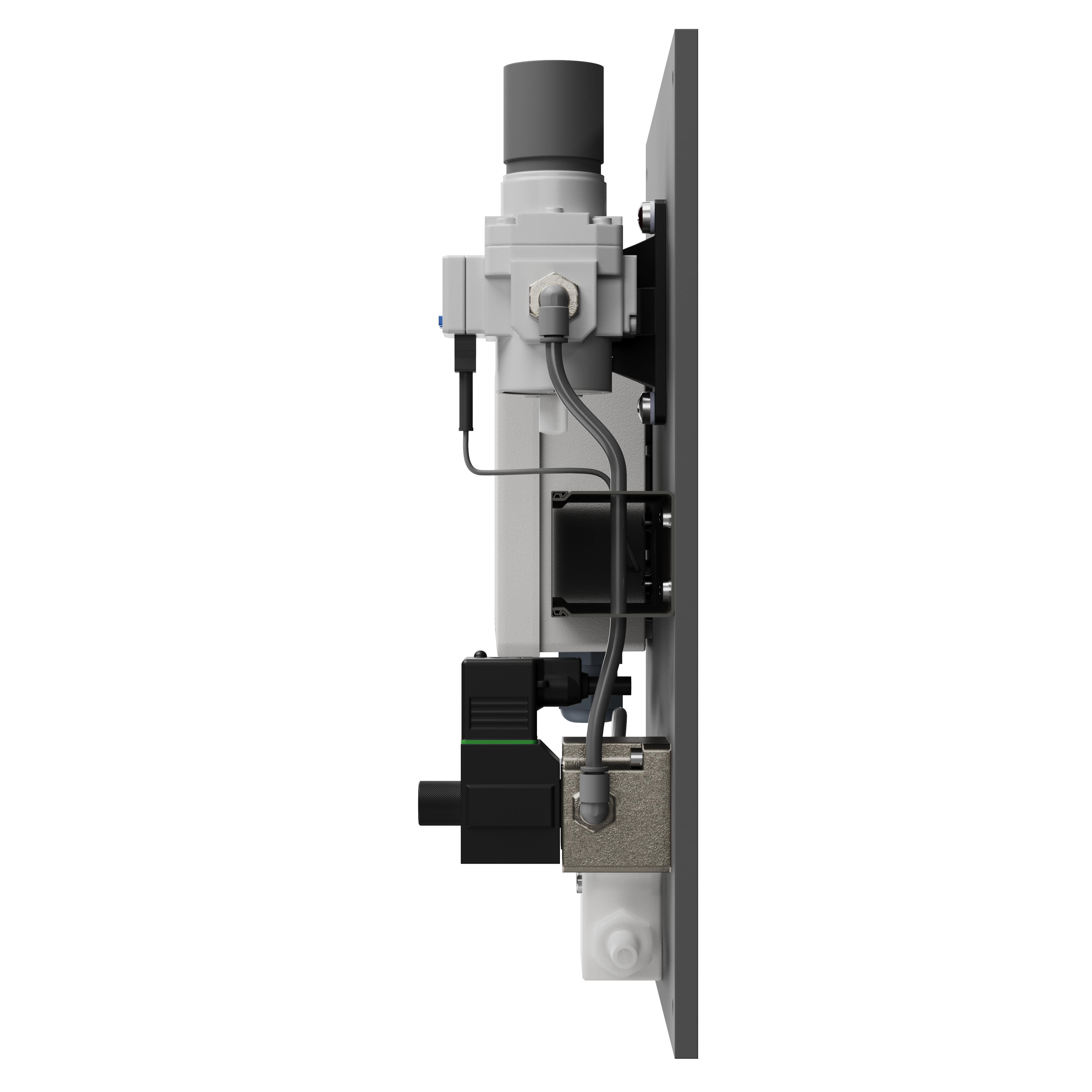

Modularity

Optimise your setup by expanding with additional channels to the central unit, saving space and lowering investment costs.

Select from a variety of configurations accommodating up to 12 machines and offering a choice of up to 10 chemical options.

Multiplex, the intelligent large-scale dosing

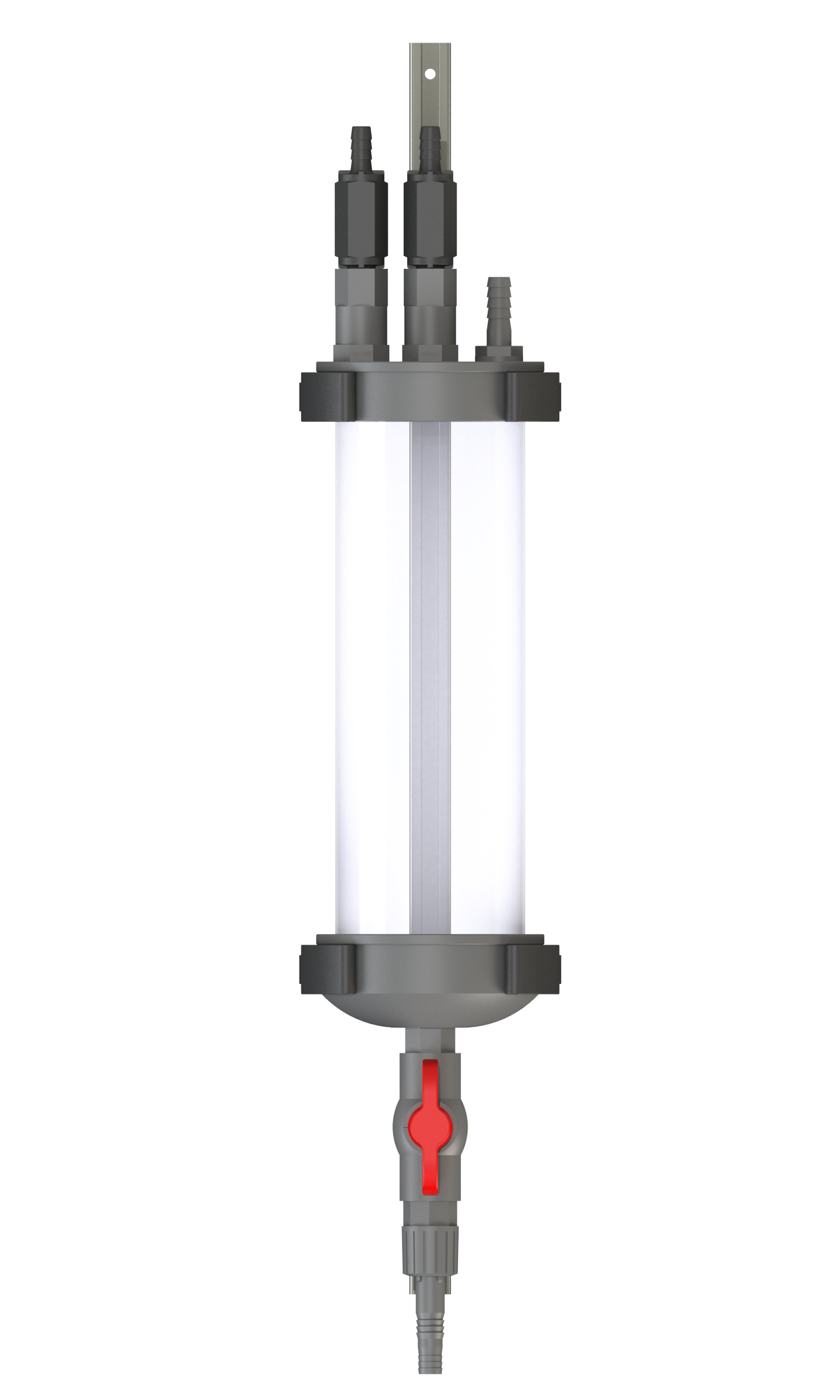

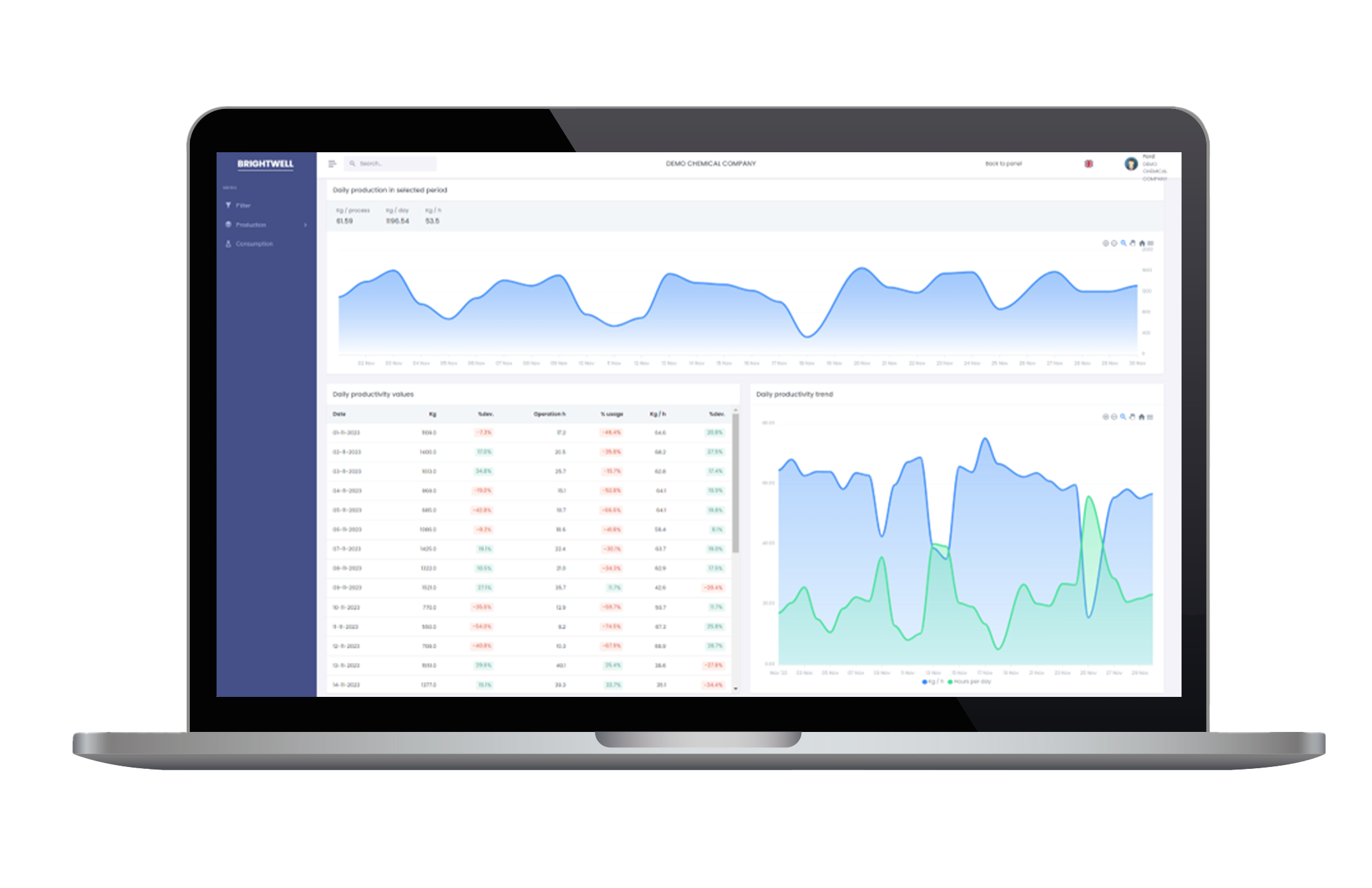

Multiplex – Digital services

Laundry management with superior digital services tailored

for high-volume chemical dosing and comprehensive

digital features ensuring efficient operation and safety

across diverse industrial environments.

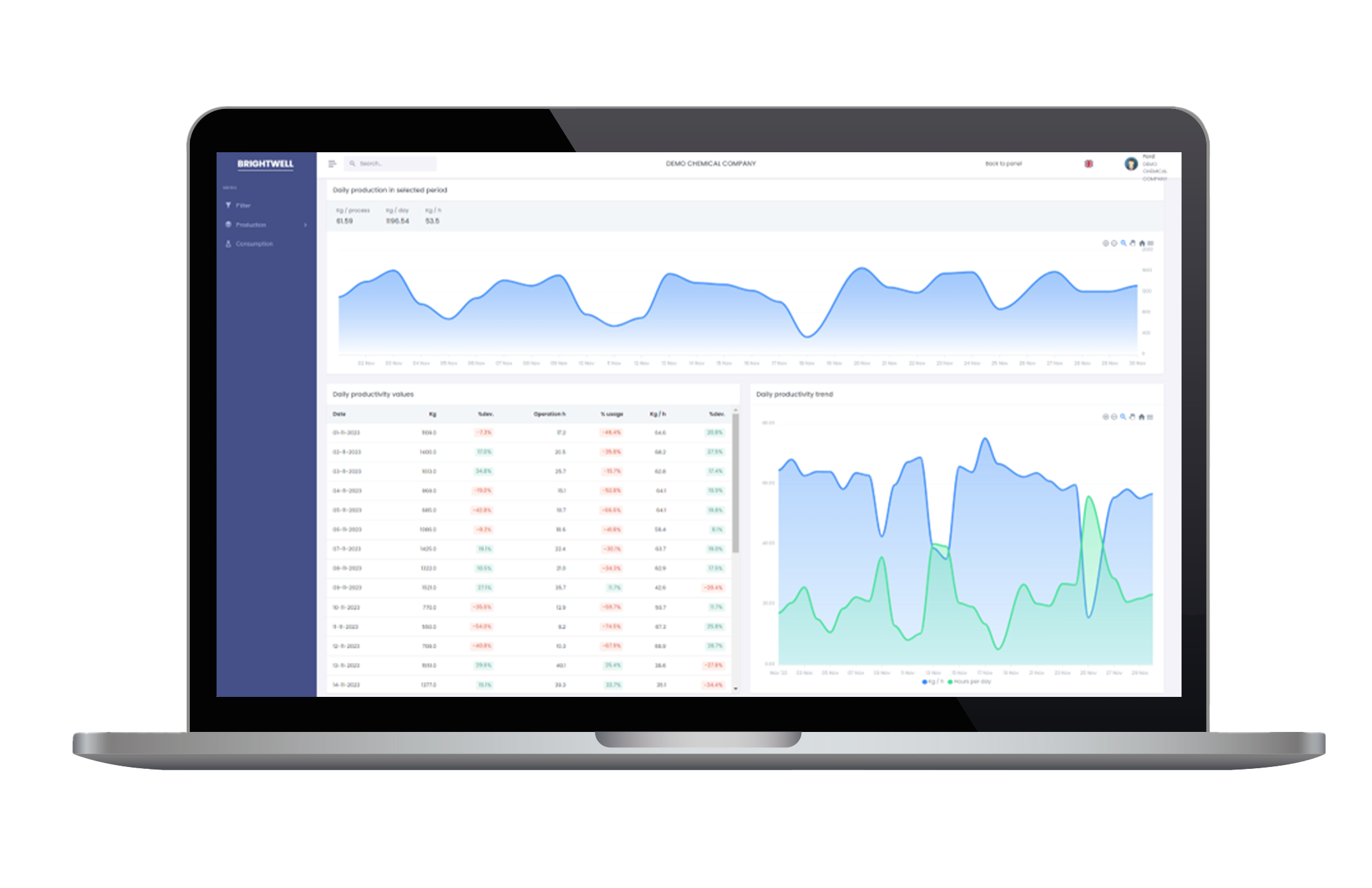

Reporting features

Software features & benefits

Advanced product catalogue

Valuable insights with reporting features

- Optimize Your Operations: Analyse Overall Equipment Effectiveness (OEE) with visual comparisons to identify areas for improvement.

- Drill down for details: Conduct program and washer analysis, and review daily program reports to pinpoint efficiency gains.

- Troubleshoot with ease: Leverage breakdown views for swift troubleshooting and problem resolution.

- Maintain control: View machine dosage programs and track dosage usage directly on-screen.