Brightwell foam range

Foam cleaning systems

Experience optimal cleaning and disinfecting

results with visible foam to ensure complete

coverage of all areas.

Visibly effective application for any environment

Our efficient and easy-to-use foam systems ensure all areas, even the hard-to-reach spots, are evenly coated with cleaning and disinfectant chemicals, stopping the spread of germs in any facility. Plus, the visible foam makes it easy to confirm exactly where the product has been applied, maintaining a pristine environment!

The Foam range

EcoFoamer

EcoFoam station 2 chemical

EcoFoam station 1 chemical

EcoFoam cart

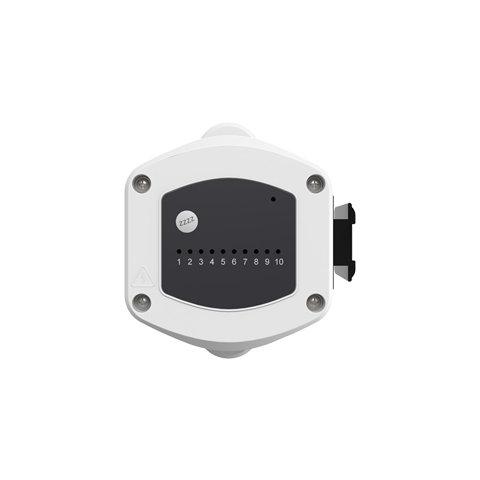

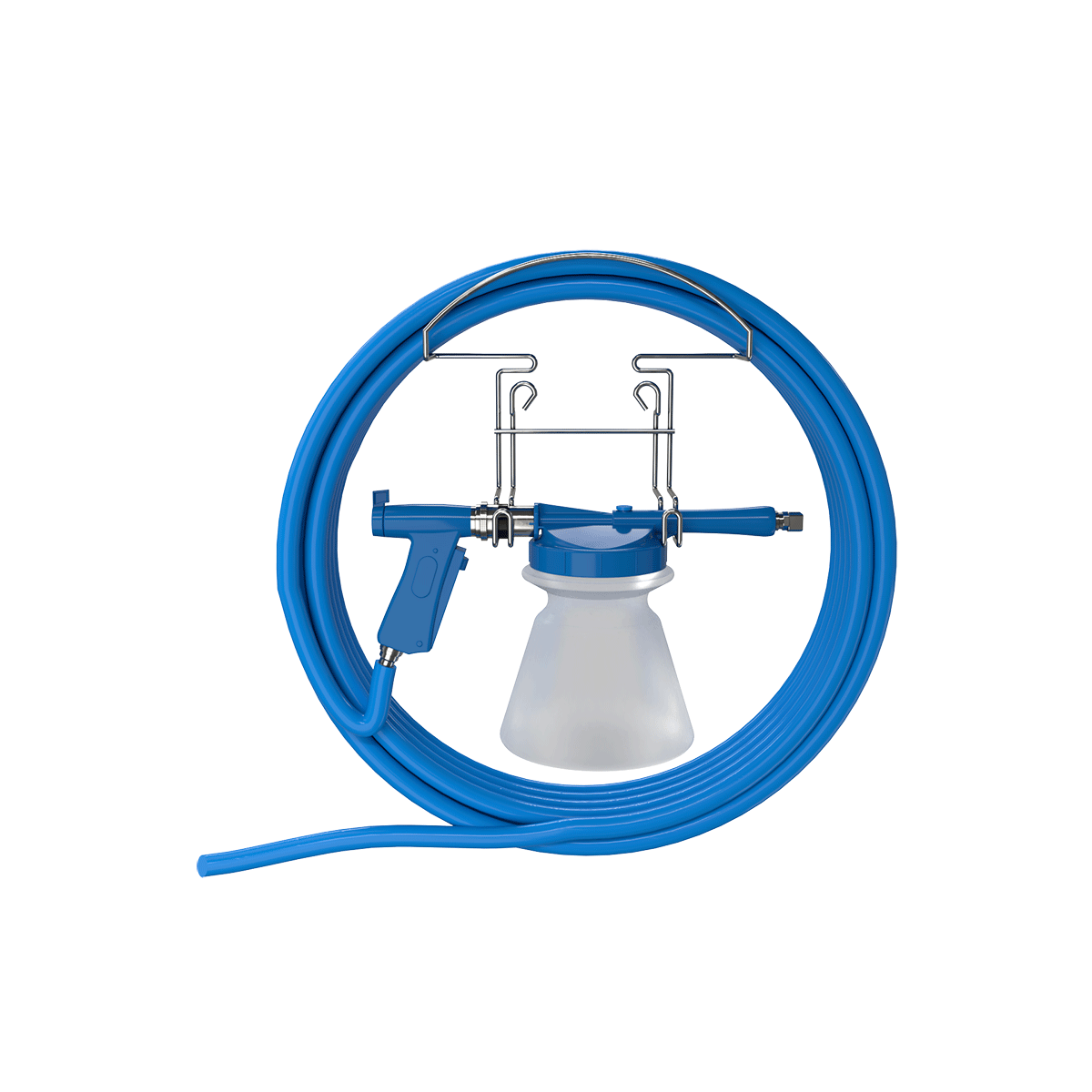

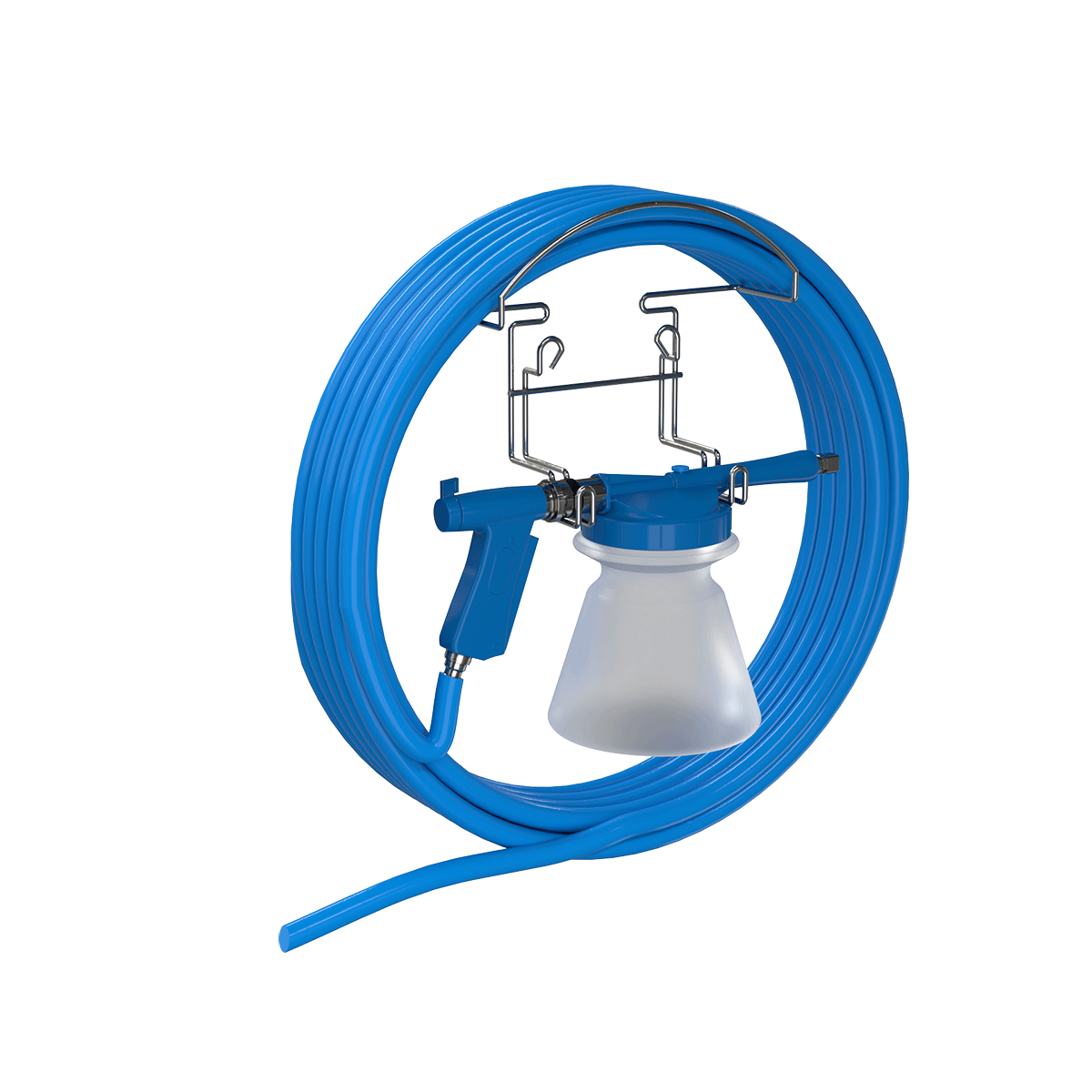

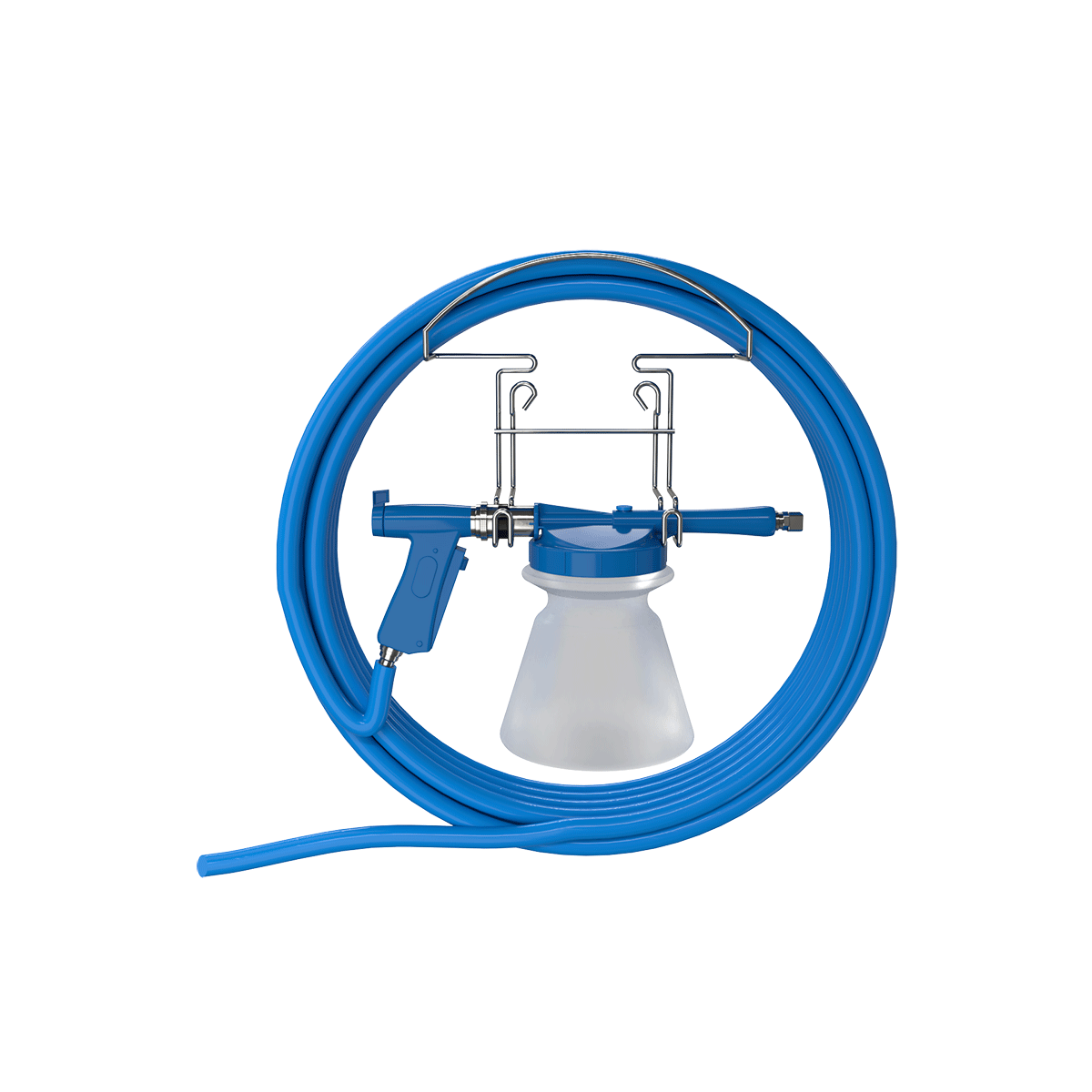

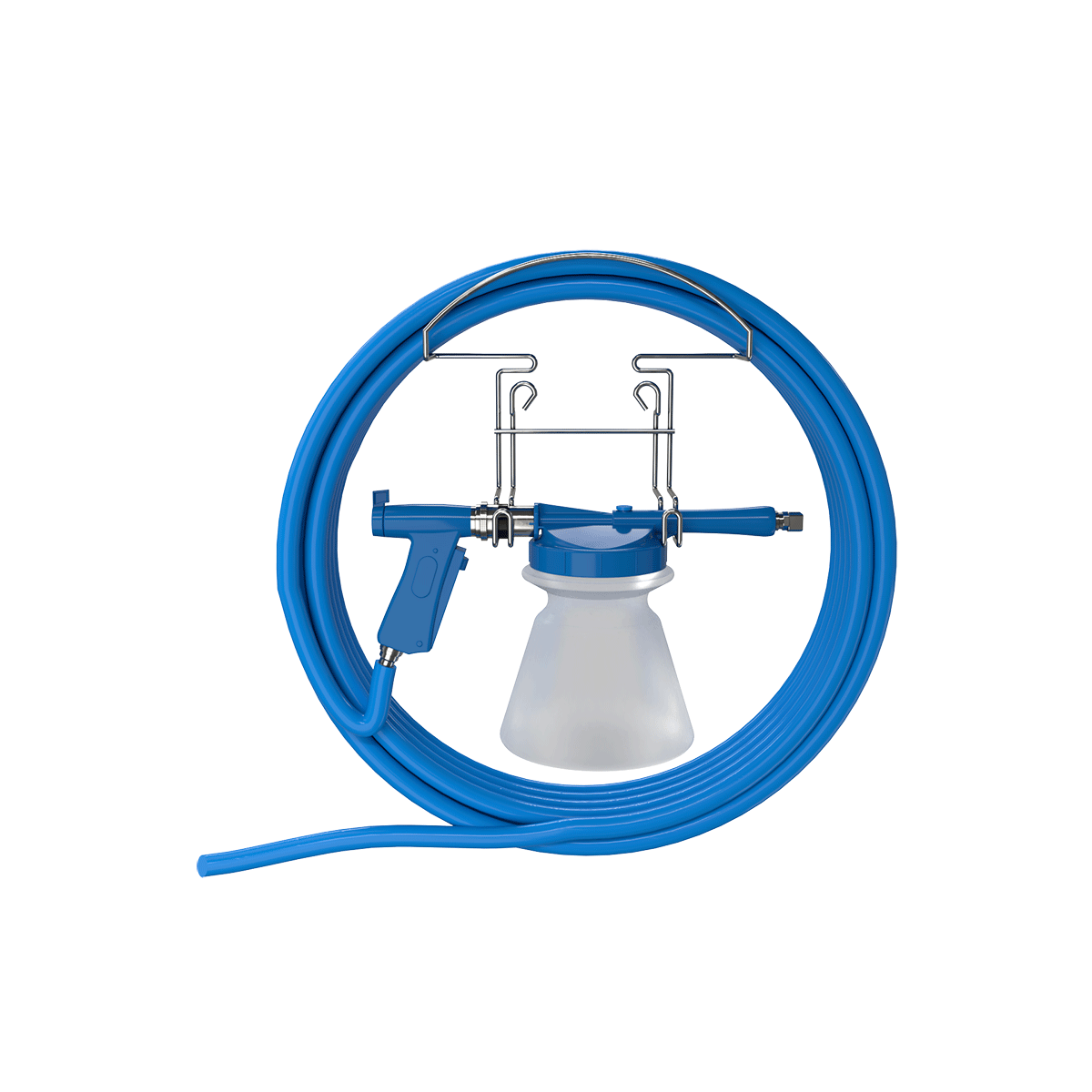

EcoFoamer

Our EcoFoamer is perfect for quickly and efficiently cleaning and disinfecting small to medium-sized surfaces. The foam makes it easy to visually confirm that all areas have been covered, ensuring a thorough clean every time. Our foam cleaning system is widely used across various sectors, including agriculture, commercial kitchens, food preparation, hospitals, and more.

With a Venturi integrated into the lid and durable polypropylene components, the EcoFoamer is simple to use and built to last. It’s compatible with most foaming chemicals, whether alkaline or acidic and the integrated stainless-steel nozzle offers a flat jet spray for optimum operation. The system requires access to mains water and is available with 1 litre or 2.5 litre containers.

Features

- Easy cleaning of small and medium surfaces, saving time and effort

- Foam nozzle spray pattern provides widespread coverage

- Wide operating pressures from 1.5 bar to 8 bar

- Easily detach foam gun and add wand for rinsing

- Capacity options with container capacities of 1 litre or 2.5 litre for larger areas

- Standard with 12.5m hose making it easy to move around and clean different areas (additional lengths available)

- Optional wall bracket for easy storage

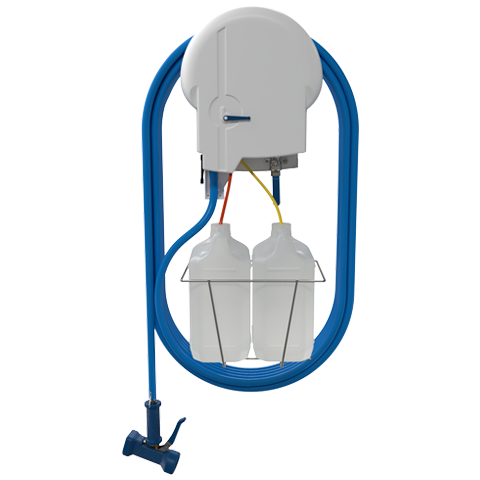

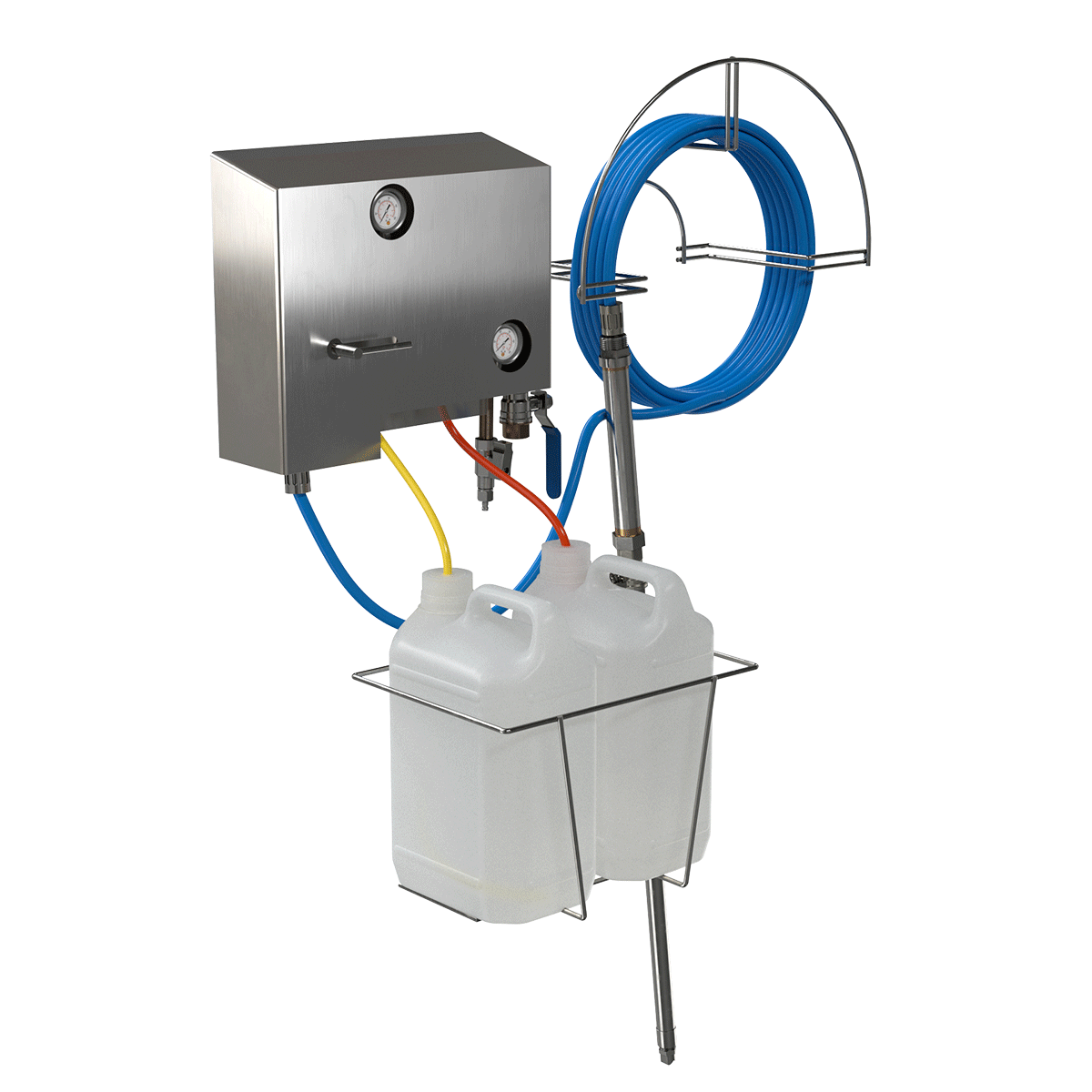

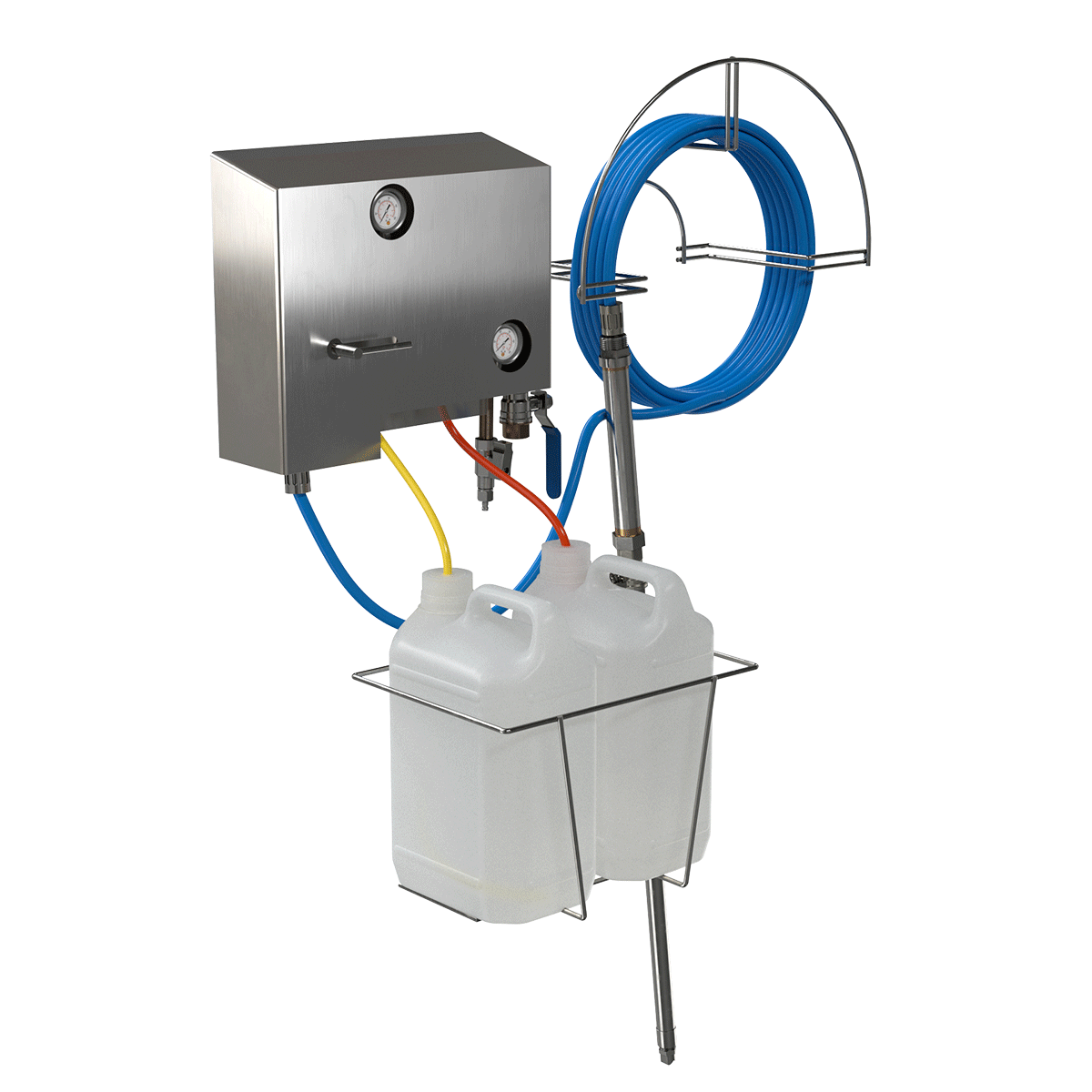

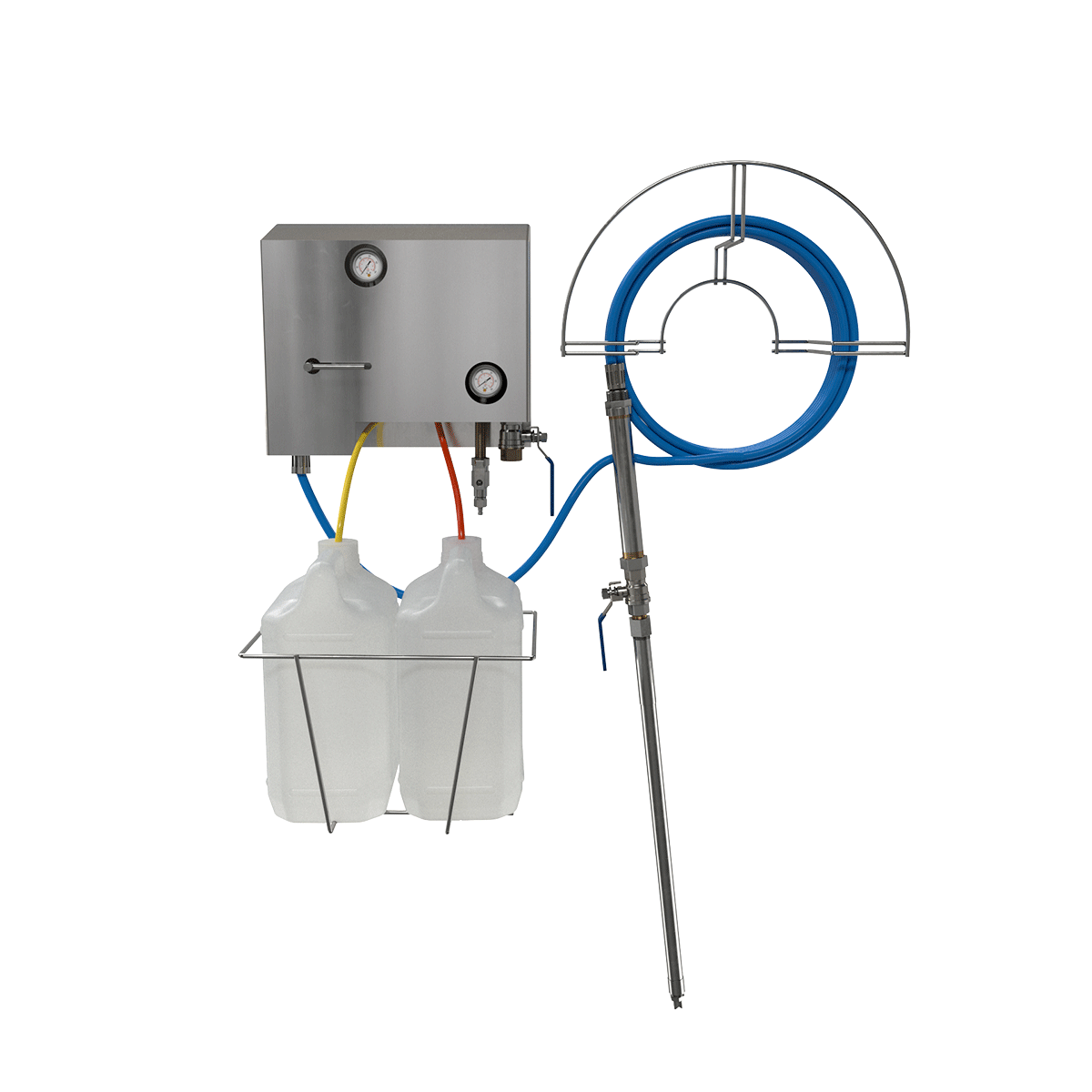

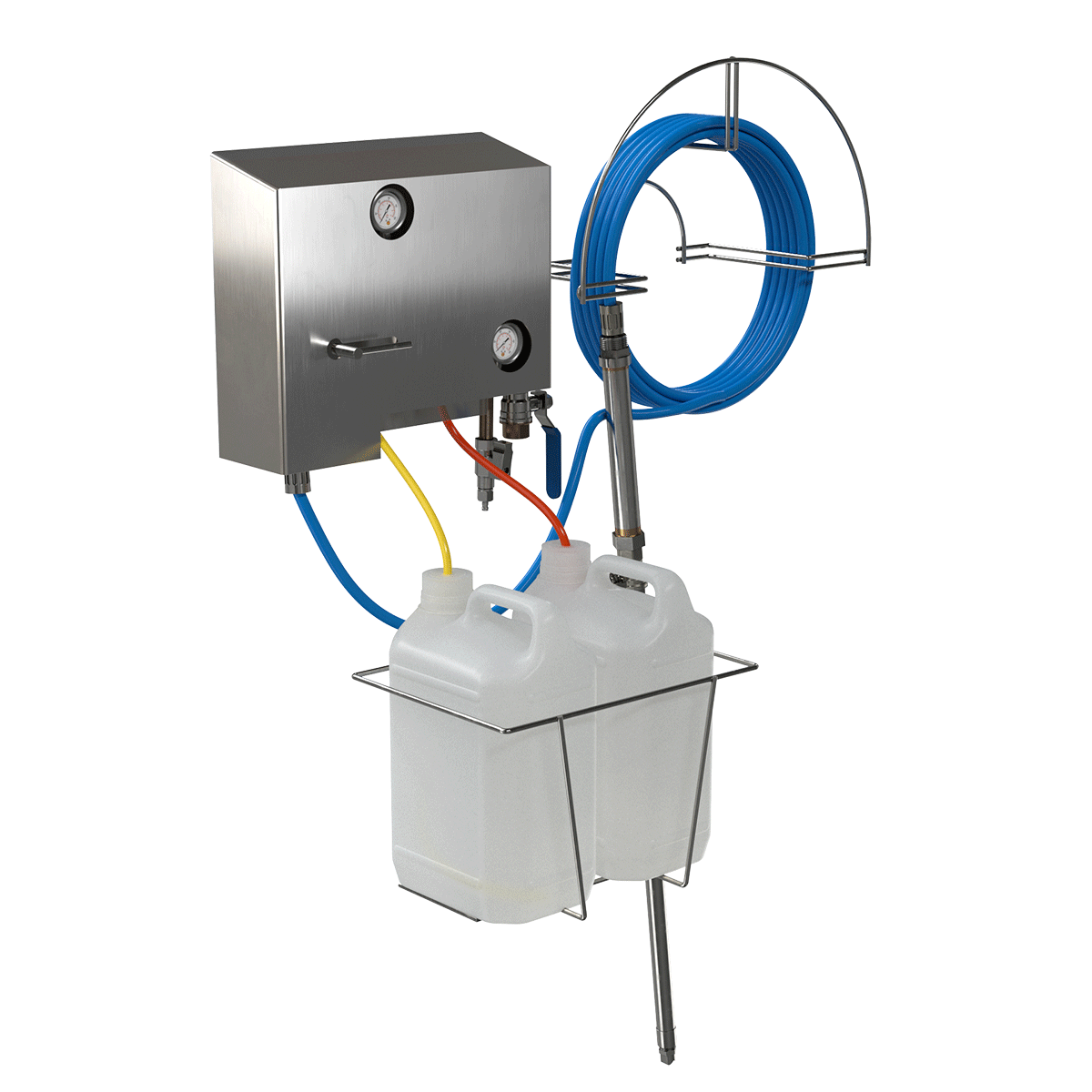

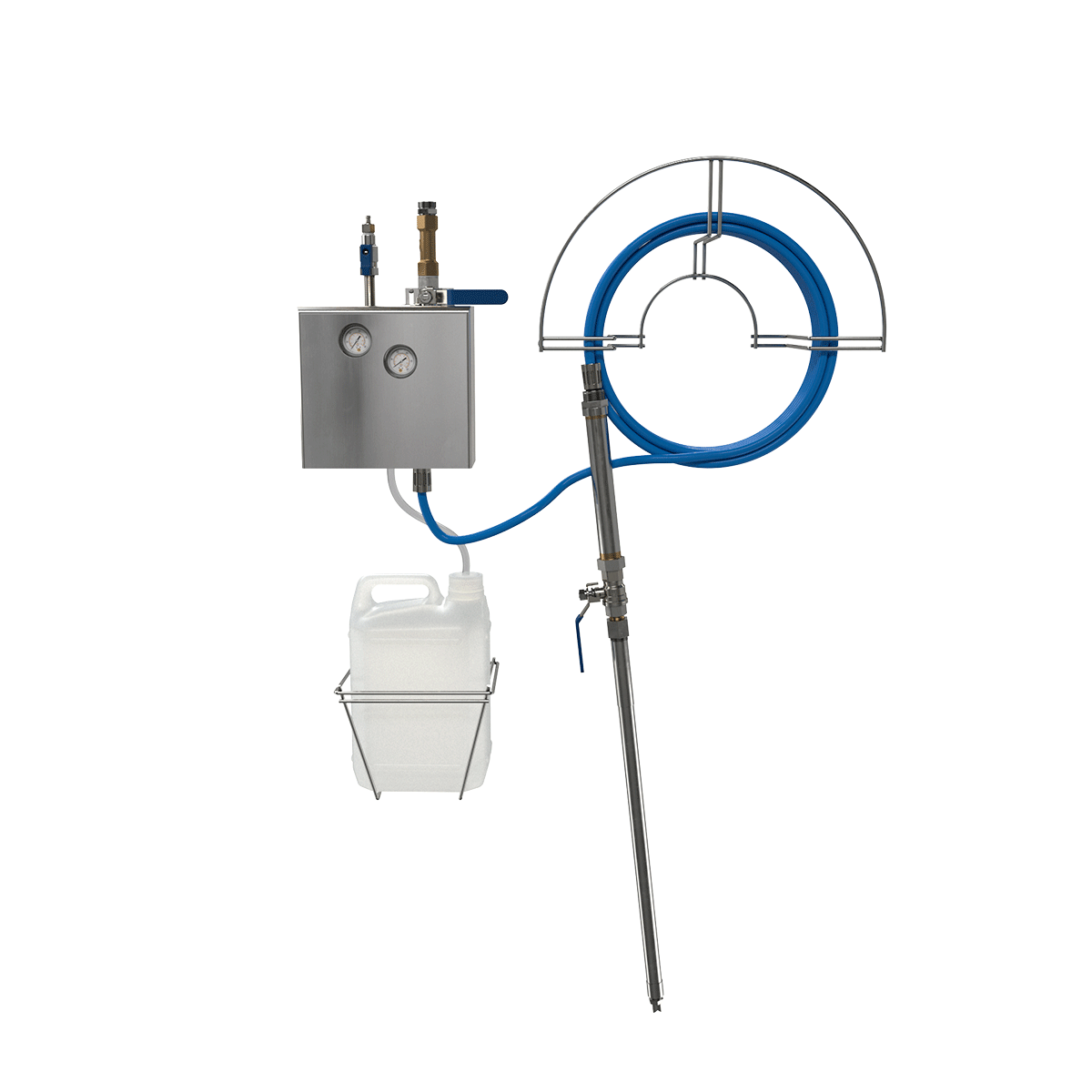

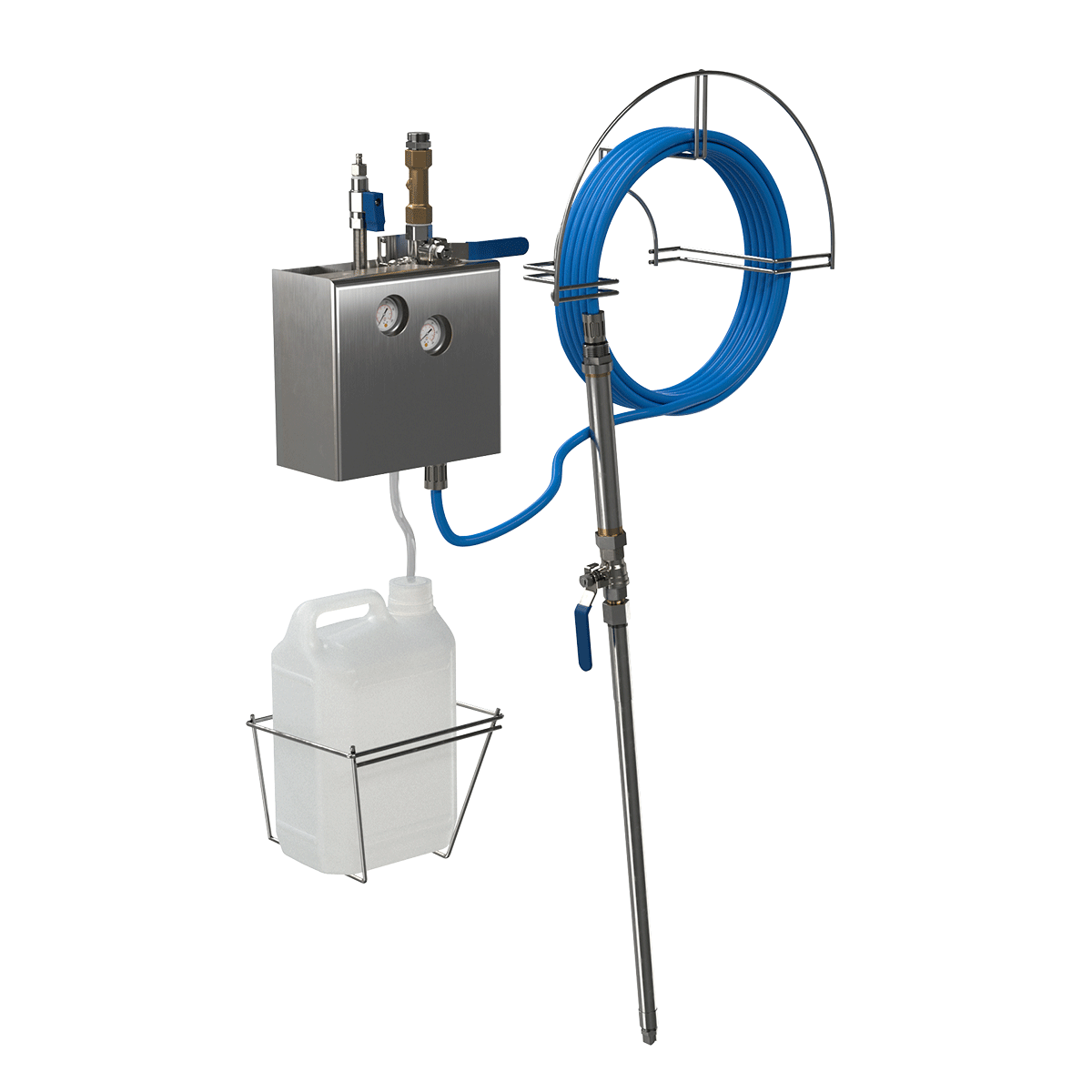

EcoFoam station 2 chemical

Our EcoFoam cleaning solution is perfect for environments that require cleaning with multiple products, with chemical selection or plain water rinse being made via a simple selector handle.

The EcoFoam station is ideally suited for use in the food industry, hospitals and commercial kitchens, where strict cleaning and hygiene requirements apply.

The system is quick and easy to use, requiring only a connection to an air supply and mains water. The system is made with a durable stainless-steel housing and incorporates backflow prevention to protect the water supply. The polypropylene venturi injector with an integrated non-return valve (standard EPDM, optional Viton) ensures that the system is safe and reliable to use.

Features

- 2 product version for multi chemical use, with optional rinse

- Easy cleaning of large areas, saving time and effort

- Foam lance allows for targeted and widespread coverage

- Metering tips provide accurate and consistent dilution ratios for your chemical

- Standard with a 15m foam hose with an integrated air hose and diffuser

- Wide operating pressures from 2.0 bar to 5.5 bar (water) and 1.8 bar to 4 bar

- Non-return valve options to suit your chemical (EPDM as standard, Viton optional)

- Intergrated backflow prevention to suit regional requirements (DC, CA or BA)

- Optional wire racks to raise chemical from floor

- Branding option available to promote company identity

Accessories

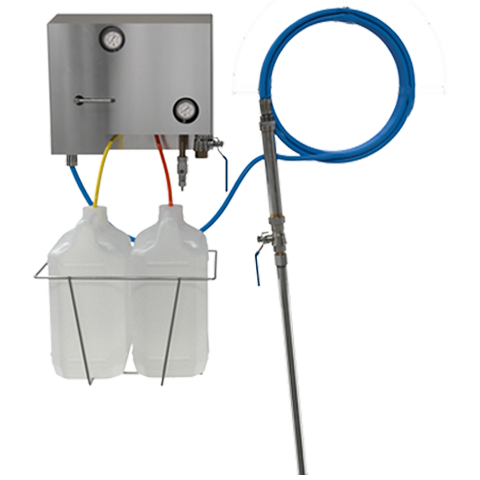

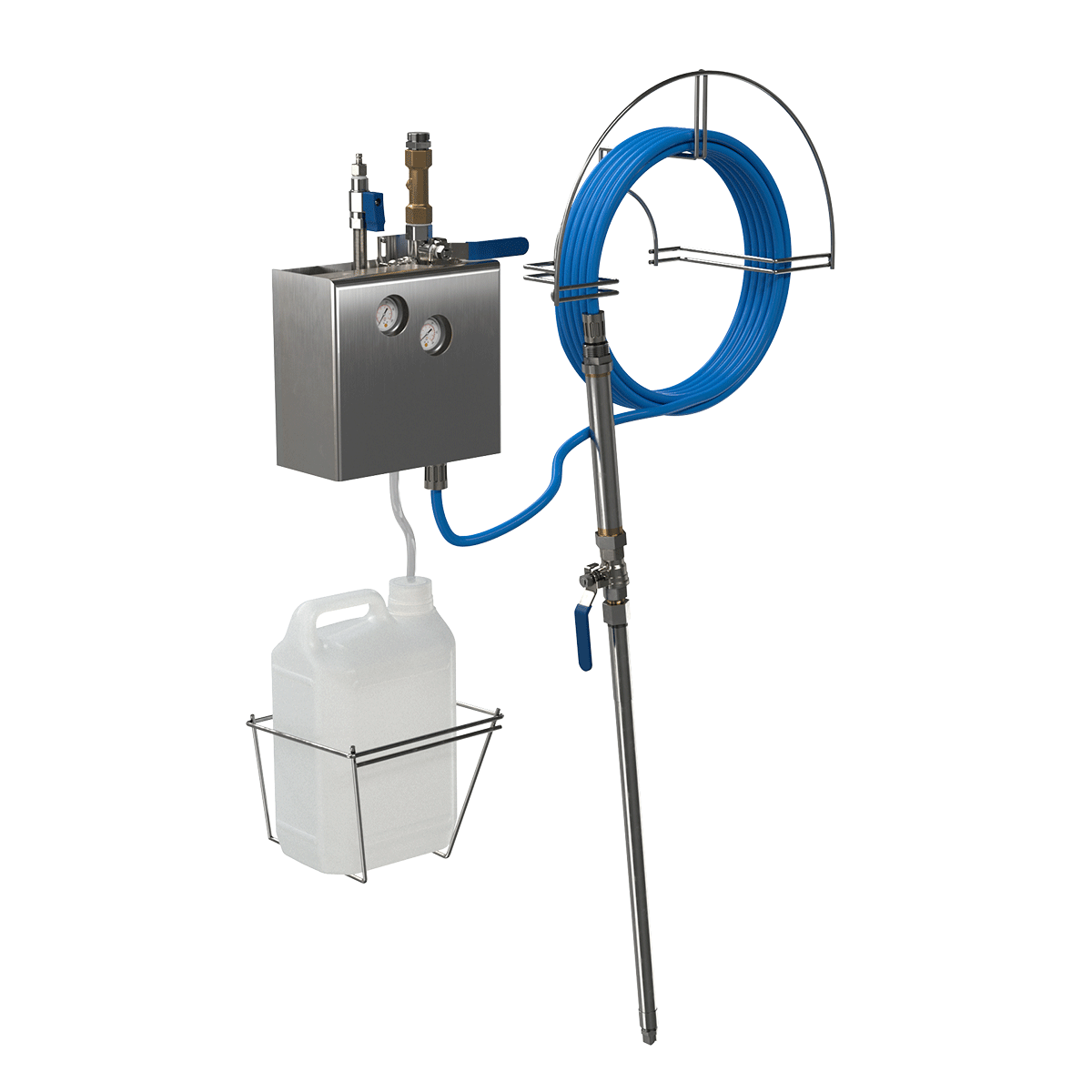

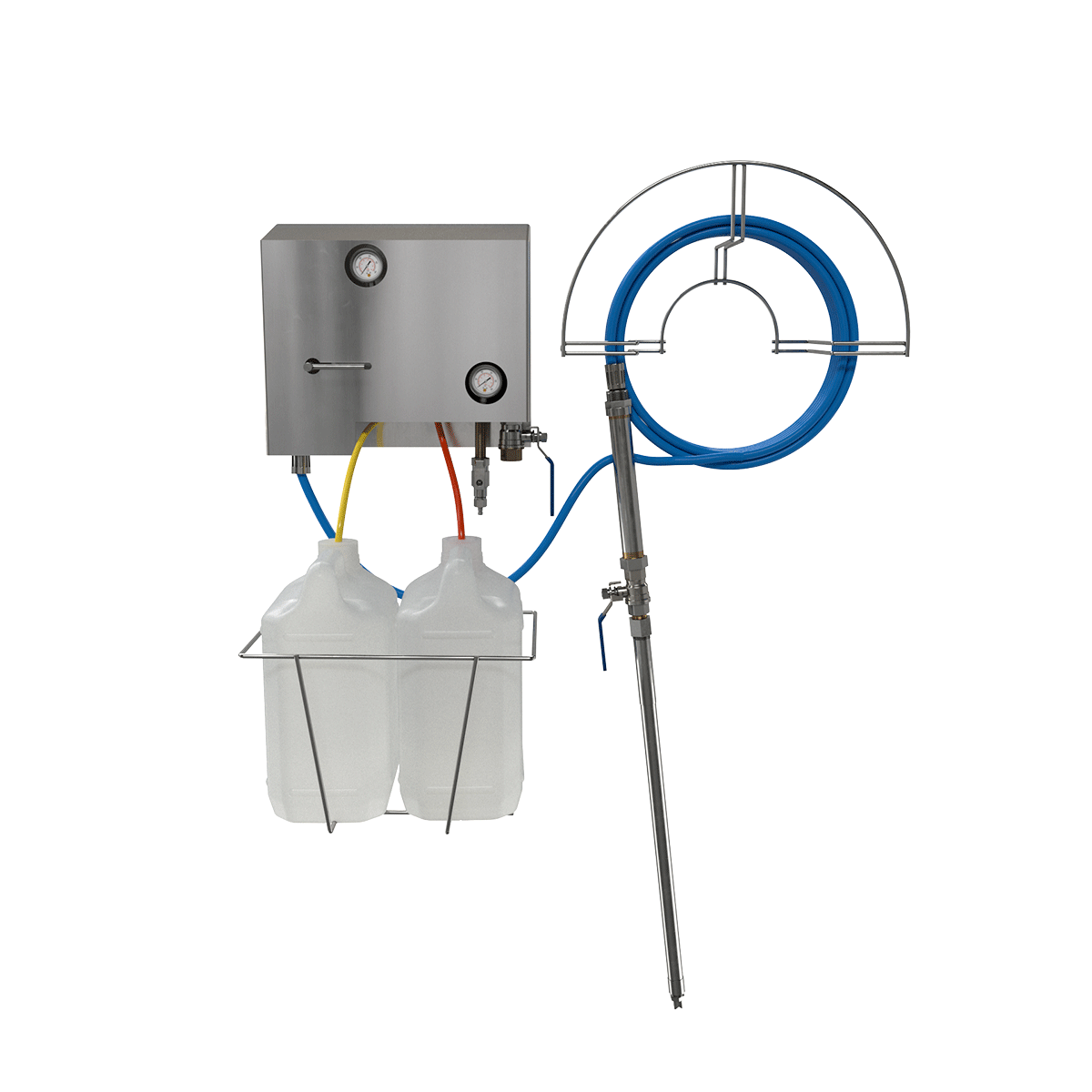

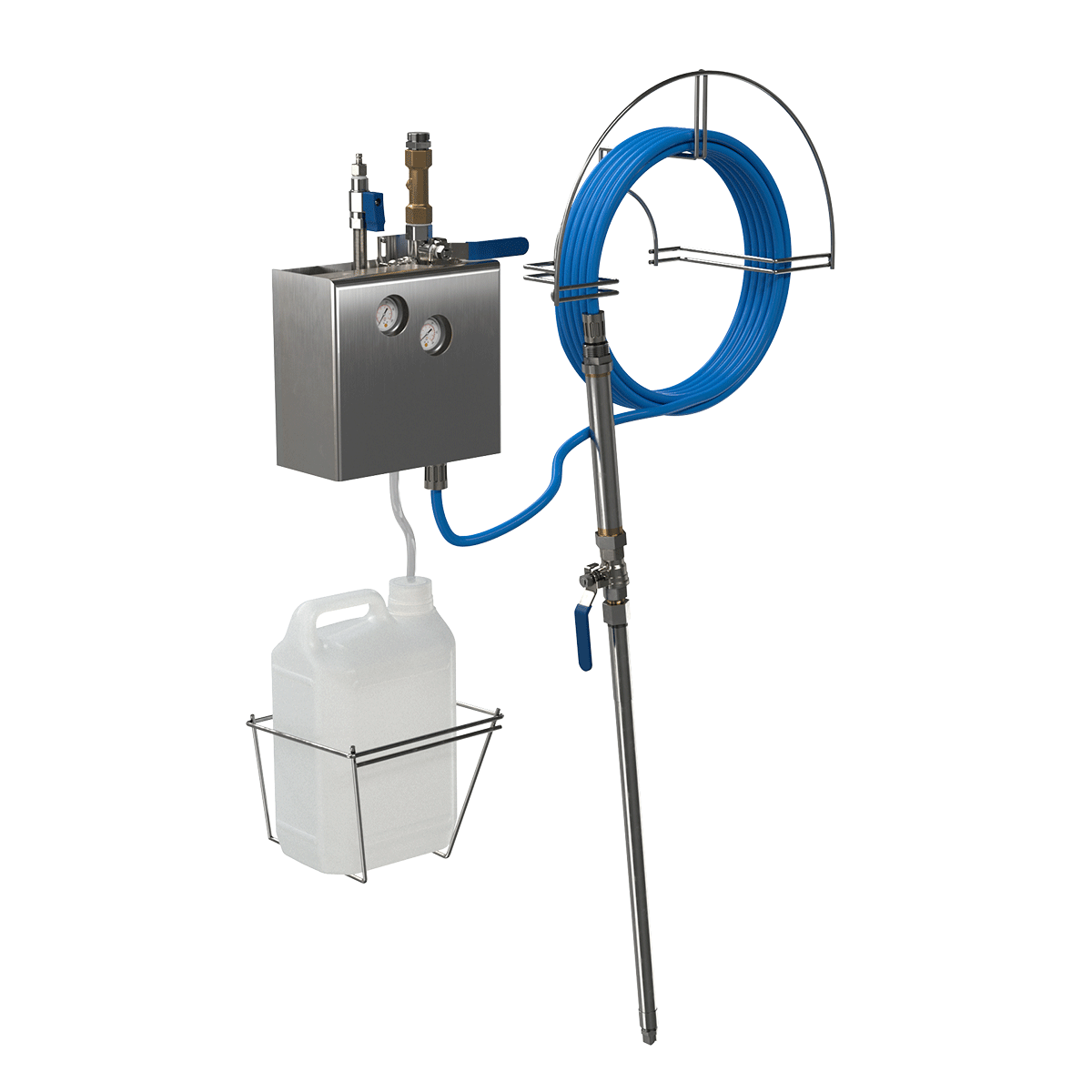

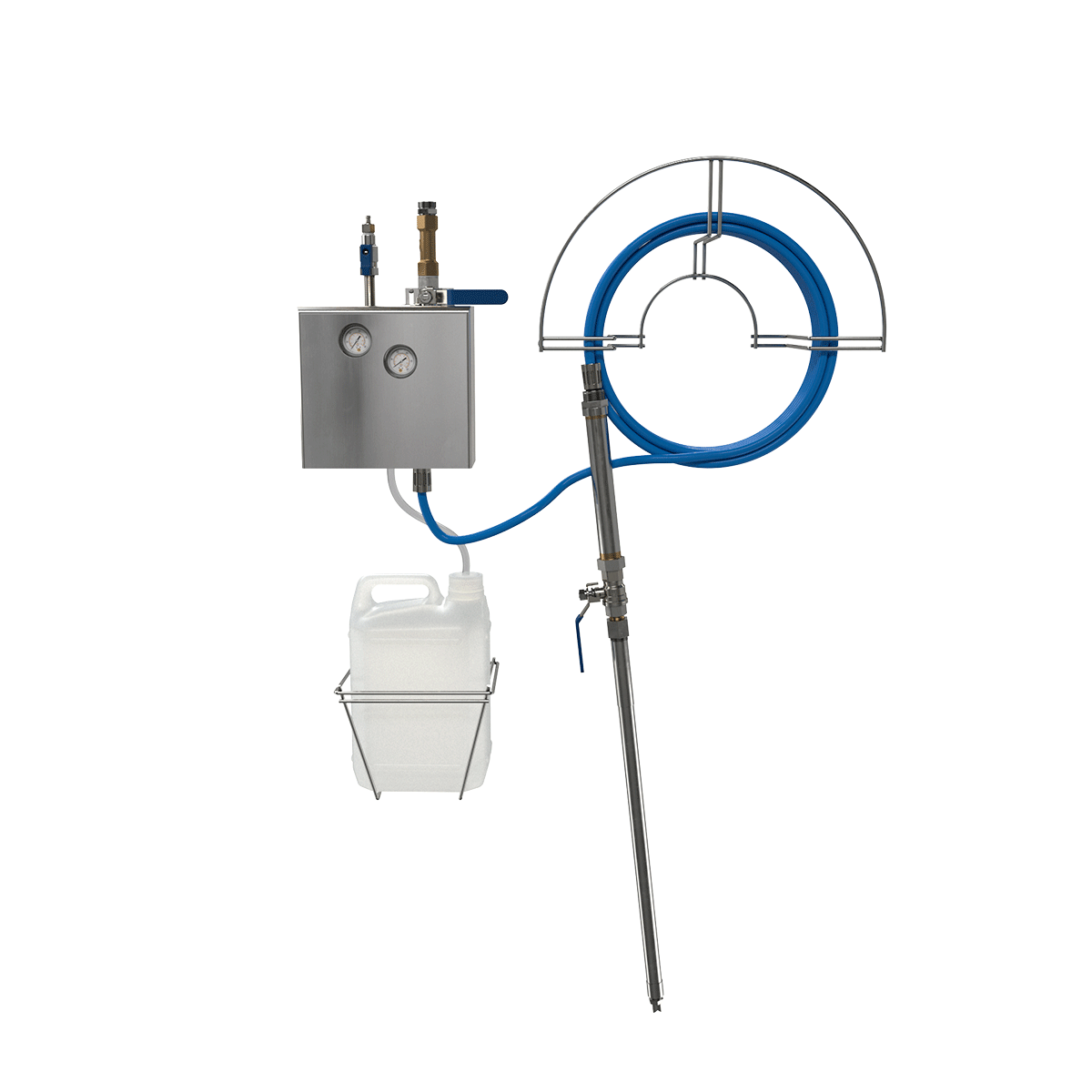

EcoFoam station 1 chemical

Our foam cleaning and disinfecting station is the perfect solution for those who need to clean surfaces using a single foaming product. The dispensing of foam provides a visual confirmation of where the cleaning product has been applied and helps ensure every area is treated. The integrated rinsing option allows water only through the hose via a simple selector handle. It is widely used in the food industry, hospitals, and commercial kitchens, where strict cleaning and hygiene rules apply.

The system is quick and easy to use, requiring only a connection to an air supply and mains water. The system is made with a durable stainless-steel housing and incorporates backflow prevention to protect the water supply. The polypropylene venturi injector with an integrated non-return valve (standard EPDM, optional Viton) ensures that the system is safe and reliable to use.

Features

- Easy Cleaning of large areas with optional rinse, saving time and effort

- Foam lance allows for targeted and widespread coverage

- Metering tips provide accurate and consistent dilution ratios for your chemical

- Standard with a 15m foam hose with an integrated air hose and diffuser

- Wide operating pressures from 2.0 bar to 5.5 bar (water) and 1.8 bar to 4 bar

- Non-return valve options to suit your chemical (EPDM as standard, Viton optional)

- Intergrated backflow prevention to suit regional requirements (DC, CA or BA)

- Optional wire racks to raise chemical from floor

- Branding option available to promote company identity

Accessories

EcoFoam Cart

Our EcoFoam Cart is expertly designed for high-performance cleaning of vertical and uneven surfaces. Ideal for the food and beverage sector, it provides the mobility needed to clean equipment effectively. Thanks to its air pump, the cart generates a rich, thick foam from a premixed solution without requiring pressure. This foam allows for easy visual confirmation that all areas are thoroughly covered, ensuring a deep clean every time.

It is also compatible with most foaming chemicals, whether alkaline or acidic, offering versatile cleaning performance. The only requirement for use is a compressed air supply, and its easy maintenance makes it one of the most convenient surface cleaning solutions in its class.

Features

- Portable and easy to use, ideal for cleaning of vertical and uneven surfaces, saving time and effort

- No electrical connection required

- Capacity options with tank capacity of 60 litre or 95 litre for larger areas

- Standard with 9m hose and lance making it easy to move around and clean different areas